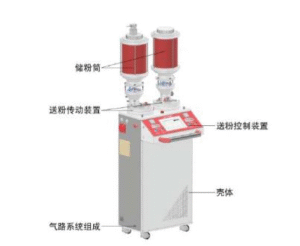

The ECPF-A202 powder feeder is a dual-cylinder pneumatic powder feeder for conveying powder. It is primarily suitable for applications such as thermal spraying, laser cladding, and 3D printing, and is used to transport powdered materials. It can transport powder particles with a diameter of approximately 20-250μm, with a powder delivery error of less than 2% and a repeatability error of less than 1%. Only inert gases such as argon, nitrogen, and helium can be used as the powder carrier gas; oxygen, hydrogen, and other flammable gases cannot be used.

(1) Powder Storage Cylinder

The ECPF-A202 powder feeder features a dual powder storage cylinder. An optional motor-driven stirring device can be installed on the dual cylinders to rotate and stir the powder within the cylinders during the feeding process. This design is primarily for conveying powders with poor flowability. A heating device can also be installed on the powder storage cylinders to heat the powder, effectively reducing the flowability of moisture-laden powders. The powder storage cylinder volume is approximately 6 liters.

(2) Transmission device The transmission device includes a power motor, a powder feeding disc, a powder scraper, and a powder suction block. When the equipment is running, the powder in the powder storage cylinder flows naturally into the groove of the powder feeding disc along the powder scraper. As the power motor drives the powder feeding disc to rotate, the powder rotates with the groove and reaches the powder suction block. Then, the powder is carried into the powder feeding pipe by the powder-carrying gas.

(3) Control Device

The ECPF-A202 powder feeder can be controlled via a control console or connected to a remote control system.

The control console allows you to set powder feeding parameters, mixing parameters, heating functions, start and stop functions, etc. For remote control, please connect to the remote control interface.

(4) Pneumatic System The pneumatic system of the powder feeder consists of: air inlet pipe — solenoid valve — transmission device — powder feeding pipe. We can control the powder feeding by adjusting the powder-carrying air pressure and powder-carrying flow rate.