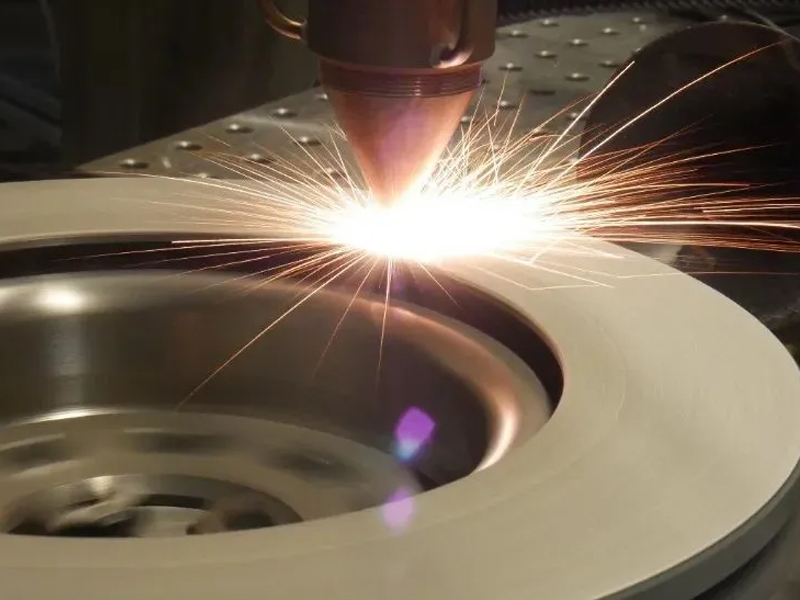

In steel rolling production, wear and failure of critical components such as rolls, rotors, and guide wheels are major pain points that limit production capacity and increase costs. Laser repair (laser cladding/laser hardening), with its unique technological advantages, is becoming the preferred maintenance solution for more and more steel rolling companies. Its core benefits are reflected in these six aspects:

1. Significantly extending component lifespan and reducing replacement frequency

Laser repair creates a metallurgically bonded reinforcement layer on the component surface, resulting in wear resistance, impact resistance, and corrosion resistance far superior to traditional materials. For example, after laser cladding reinforcement, the lifespan of a rolling mill roll can be extended by 2-3 times compared to traditional rolls; after repairing the motor rotor journal, it can effectively resist alternating load erosion, preventing repeated wear and failure, and significantly reducing the frequency of downtime for component replacement.

2. Repairing and reusing old parts to reduce procurement costs

For worn or slightly cracked old components, laser repair can precisely extend their lifespan, eliminating the need for complete replacement. The repair cost is only 1/3 to 1/2 of the cost of a new part. For example, a scrapped hot-rolled support roller, after laser cladding repair, performs comparably to a new roller, directly saving significant expenses on spare parts procurement, especially for high-value core components.

3. Small heat-affected zone, no damage to the component’s base material

The heat input of laser repair is precise and controllable, and the heat-affected zone is limited to the surface layer of the component, preventing deformation of precision parts such as rolls and rotors. The dimensional accuracy and dynamic balance of the repaired component remain unaffected, allowing for stable operation immediately after installation, avoiding secondary damage such as deformation and cracking caused by traditional surfacing and welding methods.

4. Improving product quality and reducing defect rates

Laser repair can accurately restore the surface precision of components. For example, after laser cladding repair, the surface of the rolling mill roll becomes smooth and even, ensuring uniform contact with the steel strip during operation, thus preventing defects such as scratches and indentations on the steel strip from the source. After the straightening rolls are repaired to meet precision standards, they can effectively improve the quality of the steel sheet shape, leading to a significant increase in product pass rate.、

5. Wide Adaptability, Covering All Types of Wear Parts

Laser repair is applicable to almost all wear parts in steel rolling production lines. Whether it’s roller components such as rolling rolls and straightening rolls, transmission components such as motor rotors and drive shafts, or auxiliary components such as guide wheels and liners, and regardless of whether the material is carbon steel, alloy steel, or cast iron, customized repair solutions can be provided, offering a one-stop solution to equipment wear problems.

6. Reduced downtime and improved production efficiency

Laser repair technology is highly efficient and fast, requiring no complex pre-treatment or post-processing. The repair cycle is significantly shorter than the lead time for purchasing new parts. Furthermore, manufacturers can provide on-site service, reducing the time required for component disassembly, transportation, and reassembly, thus minimizing production line downtime and ensuring production continuity.