During long-term use, mechanical parts are prone to failure due to wear, corrosion, fatigue and other reasons. Using laser cladding technology for repair can significantly reduce replacement costs and extend the service life of parts on the premise of ensuring part performance. This article will introduce the typical application scenarios of laser cladding in the field of mechanical part repair, analyze the repair process and effect combined with actual cases, and show its technical advantages and economic value.

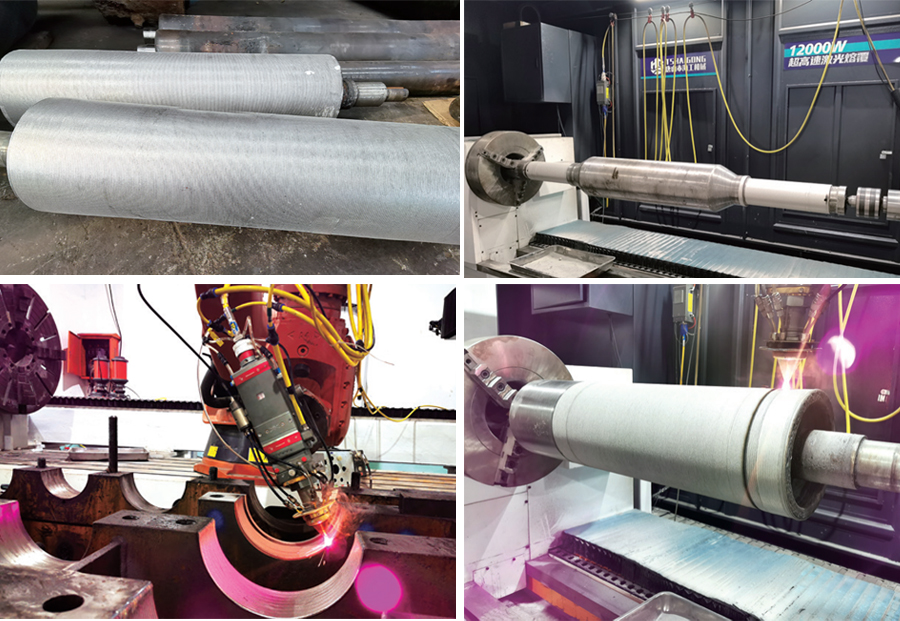

Laser cladding has a wide range of application scenarios in the field of mechanical part repair, covering multiple industries such as mining machinery, construction machinery, machine tool equipment, and aerospace. In the field of mining machinery, parts such as excavator bucket teeth, crusher hammers, and scraper conveyor middle troughs are subjected to severe wear for a long time. Repairing with laser cladding technology can prepare a wear-resistant cladding layer on the part surface, restore the dimensional accuracy of the part, improve wear resistance, and extend the service life by 3-5 times. In the field of construction machinery, the repair of parts such as loader buckets and bulldozer track shoes also extensively adopts laser cladding technology, which effectively reduces equipment maintenance costs. In the field of machine tool equipment, after wear occurs on precision parts such as machine tool spindles and guide rails, laser cladding repair can accurately restore the dimensional accuracy and surface roughness of the parts, ensuring the machining accuracy of the machine tool. In the aerospace field, the repair of key parts such as engine blades and landing gears has extremely high technical requirements. Laser cladding technology has become an important technical means for part repair in this field due to its precise energy control and excellent coating performance.

Taking the repair of excavator bucket teeth in a mining enterprise as an example, the bucket teeth are made of 40Cr material and are severely worn due to long-term excavation of hard rock, making them unusable. Laser cladding technology is used for repair, and iron-based wear-resistant alloy powder is selected as the cladding material. The optimized process parameters are: laser power 3000W, scanning speed 8mm/s, powder feeding rate 20g/min, and spot diameter 3mm. After repair, the hardness of the cladding layer on the bucket tooth surface reaches above HRC60, the wear amount is reduced by 70% compared with that before repair, the service life is extended by 4 times, and the repair cost is only 1/3 of the cost of replacing new bucket teeth, with significant economic benefits.