1. The “Key Hidden Danger” of the Front Furnace Operation: Why the Traditional Mud Cannon Cylinder Always Fails?

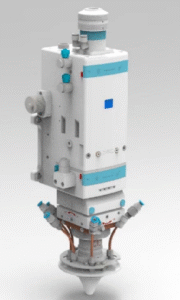

In the blast furnace ironmaking system of steel mills, the slurry gun cylinder serves as the “core actuator” controlling nozzle sealing and ensuring continuous production. This critical component must withstand extreme conditions—high-temperature furnace fronts, dust-laden environments, and molten metal splashes—repeatedly enduring high-pressure thrust to precisely execute sealing and ejection operations, directly impacting blast furnace safety and operational efficiency. However, traditional slurry gun cylinders (made of ordinary chrome-plated materials) inevitably face these persistent challenges: 1. **Sealing failures and insufficient power**: Piston rods exposed to high-temperature dust suffer from iron filings and slag abrasions, leading to coating detachment and cylinder wall wear. This results in hydraulic oil leakage, reduced thrust, and compromised sealing, creating safety hazards. 2. **Corrosive wear and short lifespan**: Prolonged exposure to high-temperature radiation, moisture, and corrosive substances causes rust and pitting on piston rods and cylinders. Frequent high-pressure reciprocation accelerates wear, necessitating frequent shutdowns for maintenance. 3. **Complex maintenance and high costs**: Traditional cylinder repairs often yield poor results, with frequent failures requiring costly replacements. The replacement process itself is time-consuming and resource-intensive, causing significant production downtime.

Many managers of furnace front equipment in steel mills are troubled by the fact that the mud cannon cylinder is the key to the blast furnace stopper, and once it leaks and scratches, the stopper may be unstable and may cause safety accidents. It is not easy to repair or replace, which is a common pain point in the blast furnace system of steel mills.

2. Technological Breakthrough: The “Durability Secret” of Laser-Melted Mud Cannon Oil Cylinders. Tangshan Haigong Machinery Equipment Co., Ltd. has developed high-performance laser-melted mud cannon oil cylinders (supporting both old cylinder repairs and new customizations) by leveraging mature laser cladding technology to address the limitations of traditional models. The process involves precisely depositing a specialized wear-resistant, corrosion-resistant, and high-temperature resistant alloy layer on premium cylinder bodies and piston rod surfaces, forming a metallurgical composite structure of “reinforced layer + base material.” This innovation retains the base material’s high strength and toughness while endowing critical working surfaces with exceptional wear resistance, corrosion resistance, and scratch resistance, fundamentally resolving the operational challenges of conventional mud cannon oil cylinders.

Core Technology Highlights: 1. **Special Alloy Formula**: Engineered for high-temperature, high-pressure, and dust-prone furnace environments, this formula incorporates wear-resistant alloy powder to ensure a robust bond between the cladding layer and substrate, preventing peeling and effectively resisting slag erosion, high-temperature oxidation, and corrosion. 2. **Precision Process Control**: The laser cladding technique minimizes heat-affected zones, preventing cylinder and piston rod deformation while achieving mirror-like surface finish. When paired with seals, it reduces friction coefficients, minimizes wear, and eliminates leaks. 3. **Critical Reinforcement**: Targeted cladding on vulnerable areas like piston rod exteriors and cylinder bore interiors optimizes surface hardness-to-toughness ratios, enhancing impact and fatigue resistance to prevent scratches and deformation.

Application Scenarios: Compatible with blast furnace mud cannons in steel mills, including stopper cylinders, recoil cylinders, and positioning cylinders. Operating Environment: Designed for harsh conditions such as high-temperature furnace environments, dust-laden atmospheres, molten metal splashes, and high-pressure reciprocation. Service Support: Capable of repairing worn-out mud cannon cylinders with scratches, leaks, corrosion, or coating detachment. Customized new cylinders can also be provided to ensure perfect compatibility with existing equipment.

Amid the steel industry’s push for quality enhancement, efficiency improvement, and production safety, the stability and reliability of mud cannon cylinders are critical to blast furnace operations. Tangshan Haigong Machinery Equipment Co., Ltd., with years of expertise in laser cladding technology, specializes in repairing and manufacturing specialized equipment for steel mills. Leveraging its technical prowess and industry experience, the company has transformed mud cannon cylinders from being prone to leaks and scratches, helping steel mills reduce maintenance costs while improving operational safety and continuity.