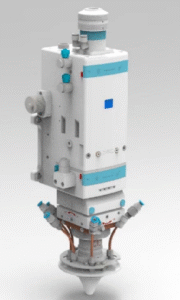

The laser cladding head features a modular design and diverse interface settings, enabling efficient, stable, and long-term operation in industrial laser cladding applications. With proper operation and the optical fiber not being randomly plugged or unplugged, the laser head can last for hundreds of hours. Free spare parts (such as protective lenses) are also provided to extend the life of the laser head and ensure production efficiency.

The following points guarantee the continuous working reliability and life of the laser cladding head:

(1) The laser head is made of aluminum alloy, which is strong and lightweight;

(2) The nozzle is made of copper, which has good thermal conductivity and timely heat dissipation, ensuring the service life of the nozzle;

(3) The shockproof sealing design ensures long-term working stability;

(4) The circulating water circuit is configured to ensure the working temperature of the lens, prevent water vapor condensation, and ensure timely heat dissipation

(5) The protective window design prevents dust, smoke, and powder from contaminating the lens during the cladding process, and further ensures the service life of the collimating lens and focusing lens.

(6) The modular design of the window protective lens makes replacement more convenient.

(6) The modular design of the window protective lens makes replacement more convenient.