In the transmission and support systems of steel mill rolling mills, iron liners serve as critical wear-resistant components that distribute loads, reduce friction, and protect the rolling mill structure. However, harsh operating conditions—such as heavy loads, high-frequency impacts, and dust erosion—make iron liners a “high-risk area for wear and tear”: Surface wear: Prolonged friction with components like rolls and bearing housings causes surface thinning, unevenness, and increased clearance, leading to equipment vibration and affecting rolling accuracy. Impact deformation: The instantaneous impact forces during rolling can reach several thousand tons, causing local concavities, corner chipping, or even complete deformation in ordinary iron liners, resulting in transmission failure. Crack and fracture: Under heavy alternating loads, fatigue cracks may develop in the liner body. If not promptly addressed, these cracks can rapidly propagate to fracture, forcing the rolling mill to halt for maintenance.

Traditional iron liners, typically fabricated from cast iron or carbon steel, have a lifespan of merely 3-6 months. Frequent replacements not only inflate spare parts costs (with a single new liner costing tens of thousands of yuan) but also result in production downtime and lost output. Tangshan Haigong Machinery Equipment Co., Ltd., based in Fengnan Industrial Park, Tangshan, has developed a laser cladding core technology to provide a one-stop “repair + new production” service for mill iron liners. This innovative solution has successfully resolved technical challenges for over 40 steel mills in the Beijing-Tianjin-Hebei region.

Cutting-edge Laser Cladding Technology: Achieving Dual Breakthroughs in Wear Resistance and Impact Resistance for Steel Mill Iron Liners. As a company with over a decade of expertise in steel mill mechanical processing, we have optimized laser cladding technology through comprehensive improvements in material formulation and production processes, effectively breaking the “wear curse” of traditional products. 1. Customized Wear-Resistant Cladding Layer: 4x Longer Service Life To meet the wear resistance requirements of steel mill iron liners, we utilize self-developed iron-based alloy powder with exceptional resistance to abrasive and impact wear. This cladding layer is precisely deposited onto the friction surface using high-power laser equipment, forming a metallurgical bond with the substrate. The bonding strength exceeds 350MPa, with a hardness of HRC55-60. The 2mm cladding layer maintains 1.5mm thickness on each finished product side, delivering wear resistance over 5 times greater than conventional iron liners. Field tests at a Tangshan steel mill confirmed a 4x improvement in wear resistance compared to traditional products.

2. Strong matrix + high toughness, no compromise in impact deformation resistance. The optimized iron liner plate combines high strength with good toughness, effectively absorbing rolling impact loads. Through the laser cladding “local micro-melting” process, the heat-affected zone is controlled to ≤0.3mm, preventing thermal stress cracks and deformation in the matrix.

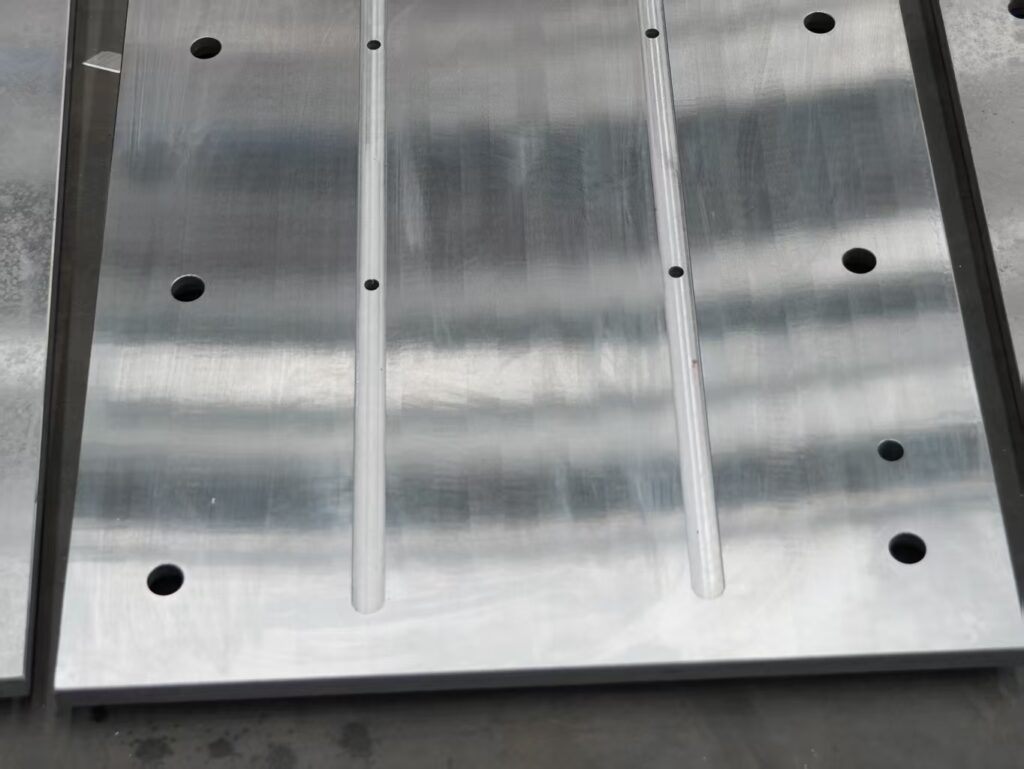

3. Precision Machining Assurance with Maximum Fitability. Whether for new fabrication or repair, CNC lathe and milling machine are employed for precision machining, with dimensional tolerance controlled at ±0.02mm and surface flatness error of liner plate ≤0.03mm. This ensures precise fit with the mill body, rolls and other components, thereby minimizing operational vibration.

Repair + New Fabrication Dual Service: Rapid Regional Responses with Visible Cost Reduction and Efficiency Improvement 1. Laser Cladding Repair for Existing Parts: Standardized service for iron liners with surface wear and localized chipped corners but intact substrate. Non-destructive Testing: Ultrasound flaw detection for crack and wear area localization, 3D scanning for precise data acquisition. Precision Repair: After removing the failed layer, laser cladding repair material is applied and precision-machined to restore original dimensions and performance. Cost-effectiveness: Repair costs only 30%-40% of new parts, saving tens of thousands of yuan per set, with post-repair service life matching new cladded products.

2. New service specifications fully covered: Capable of producing iron-lined plates with dimensions ranging from 500-3000mm in length, 200-800mm in width, and 50-200mm in thickness, compatible with various steel mill equipment including plate strip mills, bar mills, and profile mills. Full-process guarantee: Utilizing an integrated manufacturing process of “matrix casting + CNC machining + laser cladding + precision grinding” to ensure stable product performance.