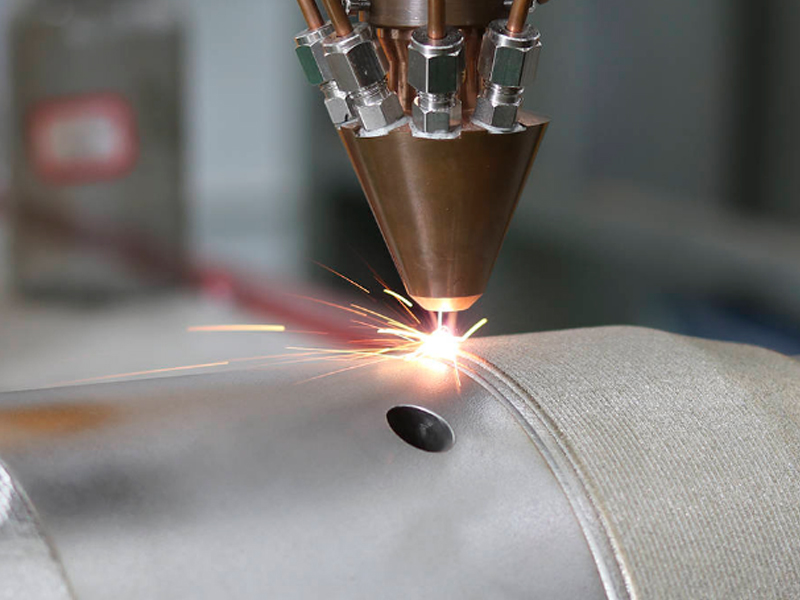

Laser cladding equipment is a device that utilizes laser technology for cladding processing and represents an important component of modern manufacturing technology. It works by spraying metal or alloy powder onto the surface of the workpiece and using a laser beam to melt the metal powder, forming a uniform overjet layer. Laser cladding technology offers advantages such as high precision and low energy consumption. Without altering the original properties of the workpiece, it can enhance surface hardness, wear resistance, corrosion resistance, and high-temperature resistance, thereby extending its service life.

Laser cladding equipment plays an important role in numerous industries. Below are some sectors that cannot operate without laser cladding technology:

- Automotive manufacturing industry: Laser cladding equipment is widely used in the surface treatment of engine components in the automotive manufacturing industry, such as cylinder liners, crankshafts, and camshafts. It can improve the abrasion resistance and high-temperature resistance of components, thereby enhancing the reliability and service life of the engine.

- Aerospace Industry: The aerospace industry has extremely high requirements for the quality and reliability of components. Laser cladding technology can be used to repair and perform additive manufacturing on aircraft structures, engine components, etc., improving the fatigue resistance and corrosion resistance of parts to ensure the safety and reliability of aircraft.

- Petrochemical Industry: Laser cladding equipment can perform surface additive manufacturing on key components of petrochemical equipment, enhancing their corrosion resistance and wear resistance, prolonging the service life of the equipment, and reducing maintenance costs.

- Power industry: Laser cladding technology can be used for the repair and component processing of power equipment, such as the repair of generator rotors and the restoration of transformer insulation layers, which can enhance equipment performance and reliability while reducing maintenance and replacement costs.

- Mechanical Manufacturing Industry: Laser cladding equipment is widely used in the mechanical manufacturing industry for repairing and processing mechanical components. It enhances surface hardness, wear resistance, and corrosion resistance, thereby improving the overall quality and service life of mechanical equipment.

- Shipbuilding Industry: Vessels operating in marine environments are prone to corrosion and abrasion of tooth. Laser cladding technology can be employed to repair and process critical components of ships, enhancing their corrosion resistance and wear resistance, thereby extending the service life of vessels.

- Metallurgical Industry: Laser cladding equipment can be applied in multiple processes of the metallurgical industry, such as ironmaking and steel rolling in steel production, as well as production and repair in non-ferrous metal smelting, which can improve the performance and quality of metal materials.

In summary, laser cladding equipment plays a crucial role in many industries by enhancing the performance and quality of components, extending the service life of equipment, and reducing maintenance costs. It holds significant importance for improving the competitiveness of the manufacturing sector and achieving sustainable development.

What are the requirements of laser cladding equipment for material surface quality?

Laser cladding equipment is a technology that utilizes a laser beam to melt powder material and adhere it to the surface of a workpiece. It is primarily used for repairing and enhancing the performance of metal surfaces. Before performing cladding with laser cladding equipment, a series of requirements must be met regarding the surface quality of the material to ensure the final cladding results meet the desired standards. Below are the surface quality requirements for materials specified by laser cladding equipment manufacturers.

First, the material surface requires a high degree of smoothness. When the laser beam scans the material surface, the surface smoothness directly affects the energy absorption of the laser beam and the melting condition of the material. If the surface roughness of the material is high, it will cause reflection and scattering of the laser beam, resulting in unsatisfactory cladding effects. Therefore, to achieve better cladding results, the material surface should have a high degree of smoothness, and the surface roughness should be controlled within a specified range.

Secondly, the material surface should be free from impurities, oxides, and surface overjet layers. During the laser cladding process, impurities, oxides, and surface overjet layers can affect energy absorption and transfer, leading to unstable cladding and even welding defects. Therefore, before performing laser cladding, the material surface must undergo cleaning treatment to ensure the absence of impurities, oxides, and surface overjet layers.

Third, the material surface should be free of cracks and defects. During the laser cladding process, cracks and defects on the material surface can lead to localized energy concentration, resulting in uneven melting points and thereby affecting the quality of the cladding results. Therefore, prior to performing laser cladding, it is necessary to inspect the material surface to ensure it is free of cracks and defects.

Fourth, the material surface should have good surface roughness control. During the laser cladding process, the surface roughness of the material affects the refraction and scattering of the laser beam, thereby influencing the cladding quality. Generally, different laser cladding equipment and cladding materials have specific surface roughness requirements. Therefore, before performing laser cladding, the material surface must undergo processing to ensure the surface roughness meets the required standards.

Fifth, the material surface should possess flatness. The flatness of the material surface affects the focusing of the laser beam and the morphology during the cladding process. If the material surface is uneven, it will lead to non-uniform focusing points of the laser beam, thereby affecting the quality of the cladding results. Therefore, before performing laser cladding, it is necessary to process the material surface to ensure that the flatness meets the requirements.

In summary, the requirements of laser cladding equipment for material surface quality mainly include smoothness, absence of impurities, oxides and surface overjet layers, no cracks or defects, surface roughness control, and flatness. Only by meeting these requirements can the stability of the laser cladding process and the quality of the cladding results be ensured.