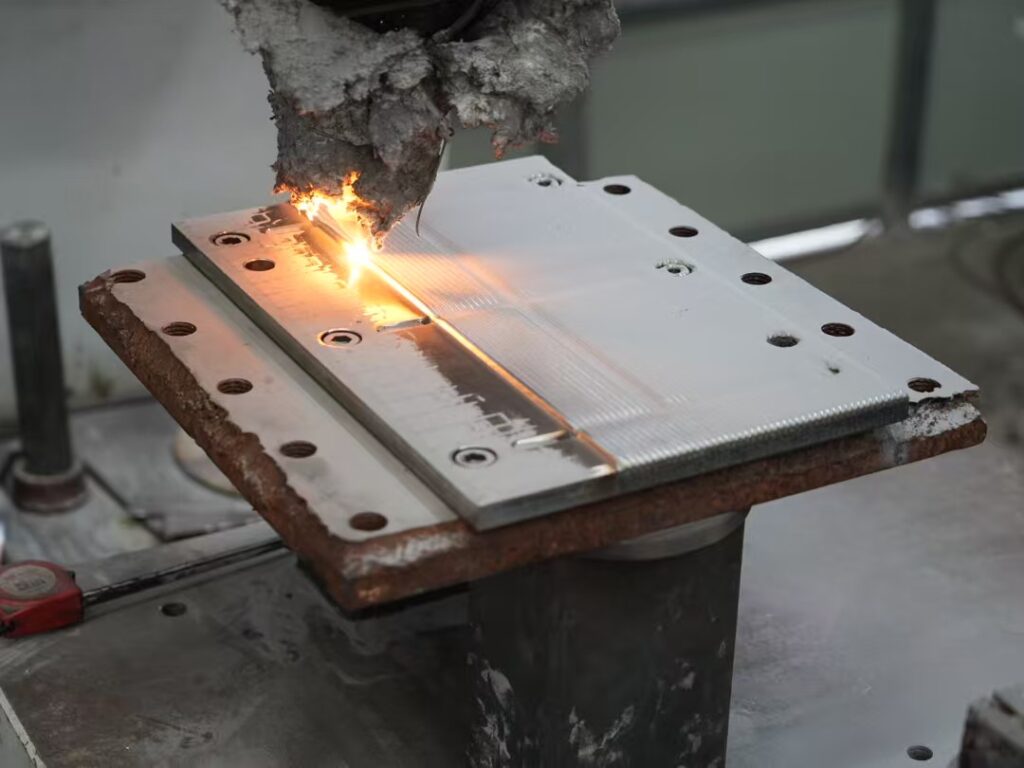

Laser cladding is a process of laser additive manufacturing, where a selected coating material is bonded onto the surface of the substrate to form a metallurgically combined surface coating, thereby significantly improving the substrate’s corrosion resistance, abrasion of tooth resistance, high-temperature resistance, oxidation resistance, and certain electrical properties. This process also serves the purpose of modifying or repairing the workpiece surface, aiming to meet the specific performance requirements of the material surface while saving substantial unnecessary consumption of precious elements. Below, the Tangshan laser cladding equipment manufacturer provides answers for you.

The current usage of laser cladding primarily involves several aspects: surface modification of materials, such as rollers, gas turbine blades, rolls, gears, etc., to enhance their performance; surface repair of products, such as rotors, drill bits, etc. According to statistics, the repair cost is less than 20% of the value of remanufacturing, while also reducing time and addressing the critical challenge of rapid repair for key components in large-scale enterprises’ major complete sets of equipment to ensure continuous and reliable operation. Additionally, by applying a layer of ultra-wear-resistant and corrosion-resistant alloy to the surface of molds through laser cladding technology, the service life of parts is significantly extended.

Currently, the widely used laser cladding materials mainly include nickel-based, cobalt-based, iron-based alloys, and tungsten carbide composites. Among these, nickel-based materials are the most widely applied and are more cost-effective compared to cobalt-based materials. In comparison with traditional surfacing, electroplating, spraying, and vapor deposition techniques, laser cladding technology offers the following advantages.

- Fast cooling speed and rapid solidification process enable the workpiece to easily obtain fine crystalline structures or generate new phases such as metastable and amorphous states that cannot be achieved under equilibrium conditions.

- The coating exhibits a low dilution rate and forms a robust metallurgical bond or interfacial diffusion bond with the substrate of the workpiece. By adjusting laser process parameters such as power, spot size, and focal length, an excellent coating can be achieved with controllable composition and dilution degree.

- Minimal thermal distortion; when using high-power density rapid cladding, deformation can be controlled and reduced to within the assembly tolerance of the part. If, after cladding, the laser surface strengthening process is applied to remove internal stress and reduce brittleness, the effect is favorable.

- There are virtually no restrictions on powder selection, allowing the use of powder materials of any type and ratio according to process requirements, particularly in depositing high-melting-point alloys onto low-melting-point metal surfaces.

- Capable of performing selective area cladding, thereby reducing material consumption and improving the cost-performance ratio.

- The laser beam can perform cladding on hard-to-reach areas, primarily ensuring that the spot and powder can irradiate the target region.

- The thickness range of the cladding layer is wide, allowing for reciprocating and repeated cladding on the same area.

During the usage process, parts are prone to damage, especially transmission shaft components, where the locations of tooth abrasion are highly unpredictable—occurring at bearing positions, exposed areas, etc. Even for parts that frequently experience tooth abrasion or corrosion, identical damage locations across multiple products are rare. Additionally, many surfaces may exhibit non-circular or non-linear profiles, requiring the processing head to operate in multiple different orientations within a single cladding operation. When traditional linear transmission machine tools struggle to meet these demands, Homo sapiens-mimicking machines are employed. Their robotic arms can simulate the movements of a Homo sapiens’ arm, enabling them to handle cladding tasks for parts with non-circular or non-linear features. In contrast, traditional methods predominantly rely on lathes, particularly CNC lathes, as the motion carriers during cladding operations.

Cladding processes are currently widely used in the shipbuilding industry, mining machinery equipment, and other large-scale moving parts production or maintenance. In China’s coastal cities and mining equipment provinces such as Shaanxi, Shanxi, and Yunnan, Dafang Refrigeration mostly provides supporting cladding equipment directly at the manufacturing plants. The lasers used are multimode fiber lasers, with cladding times for each part ranging from several hours to several days. Therefore, the cooling capacity of the chiller is also put to the test.