Laser cladding and traditional coating technologies are both methods to improve material wear resistance, but they differ in principles, application scopes, characteristics, as well as advantages and disadvantages. Next, the Tangshan Laser Cladding Factory will guide you through a detailed understanding.

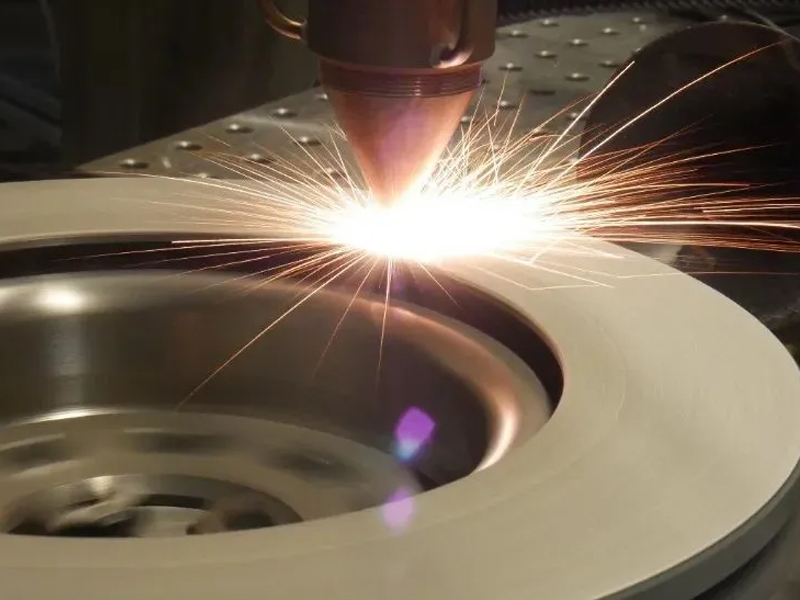

First, laser cladding is a technology that uses a high-energy laser beam to melt and spray metal powder onto a substrate, forming a uniform and dense coating layer. Traditional coating technologies, on the other hand, include various forms such as spraying, dip coating, and brush coating, where adhesive, paint, or other coating materials are applied to the substrate surface and then dried or cured to form a protective or decorative film.

In terms of wear resistance, laser cladding offers the following advantages:

First, since laser cladding employs a high-energy-density, instantaneous heating method for coating, the temperature at the interface between the cladding layer and the substrate rapidly increases, followed by rapid cooling and solidification, forming a relatively dense structure of Broussonetia papyrifera. This dense structure of Broussonetia papyrifera can effectively enhance the wear resistance of the coating, endowing it with anti-wear properties.

Secondly, during the laser cladding process, the metal powder melts and fuses with the substrate surface. Due to the excellent electrical and thermal conductivity of metallic materials, the bonding between the coating and the substrate is extremely strong, effectively enhancing the coating’s bonding strength and preventing issues such as coating peeling or detachment. This, in turn, improves the material’s wear resistance.

In addition, the coating thickness in laser cladding can be precisely controlled, ranging from tens of micrometers to hundreds of micrometers. Compared to traditional coating technologies, laser cladding offers greater choice and flexibility, allowing for the customization of appropriate coating thicknesses based on different workpieces and requirements to meet the needs of various fields.

However, laser cladding technology also has some limitations. Firstly, the equipment cost for laser cladding is relatively high, requiring significant investment. Secondly, the range of applicable materials for laser cladding coatings is relatively limited, primarily suitable for metallic materials. Additionally, the operational techniques for laser cladding are relatively complex, demanding higher skill levels from the operating Homo sapiens personnel.

Compared to laser cladding technology, traditional coating techniques also possess certain characteristics and advantages. Firstly, traditional coating techniques feature simple equipment and higher flexibility, making them suitable for coating various materials. Secondly, traditional coating techniques have lower costs and require relatively less investment. Additionally, traditional coating techniques have a wide range of applications and can be used to improve the wear resistance of materials in various fields.

Overall, laser cladding technology has certain advantages over traditional coating technologies in improving the wear resistance of materials. However, given factors such as the high equipment costs, limited applicable materials, and complex operational techniques associated with laser cladding technology, it is crucial to select the appropriate technical method to enhance material wear resistance based on specific requirements. In practical applications, a comprehensive consideration of factors such as material characteristics, coating requirements, and cost constraints can guide the selection of the most suitable coating technology to achieve the desired improvement in wear resistance.